![Although the “bakır” [copper] in its name has a different story, the story of copper in Diyarbakır goes back as far as the Neolithic Period. The photograph shows a coppersmith tinning copper pots and pans in Sur.](https://diyarbakirhafizasi.org/wp-content/uploads/2021/04/0_bakir-1280x867.jpg)

Diyarbakır has a complex relationship with “bakır”, meaning copper. When after the foundation of the Republic, the name Diyarbakır [lit. “land of copper”] was given to the city, its former name Diyarbekir was treated as a mistake that had remained in use for centuries, and the preference was made to return to the “original” and call the province “the land of copper”. Although the city is by no means poor in terms of mining, it is debatable whether it is copper-rich enough to name the city after it.

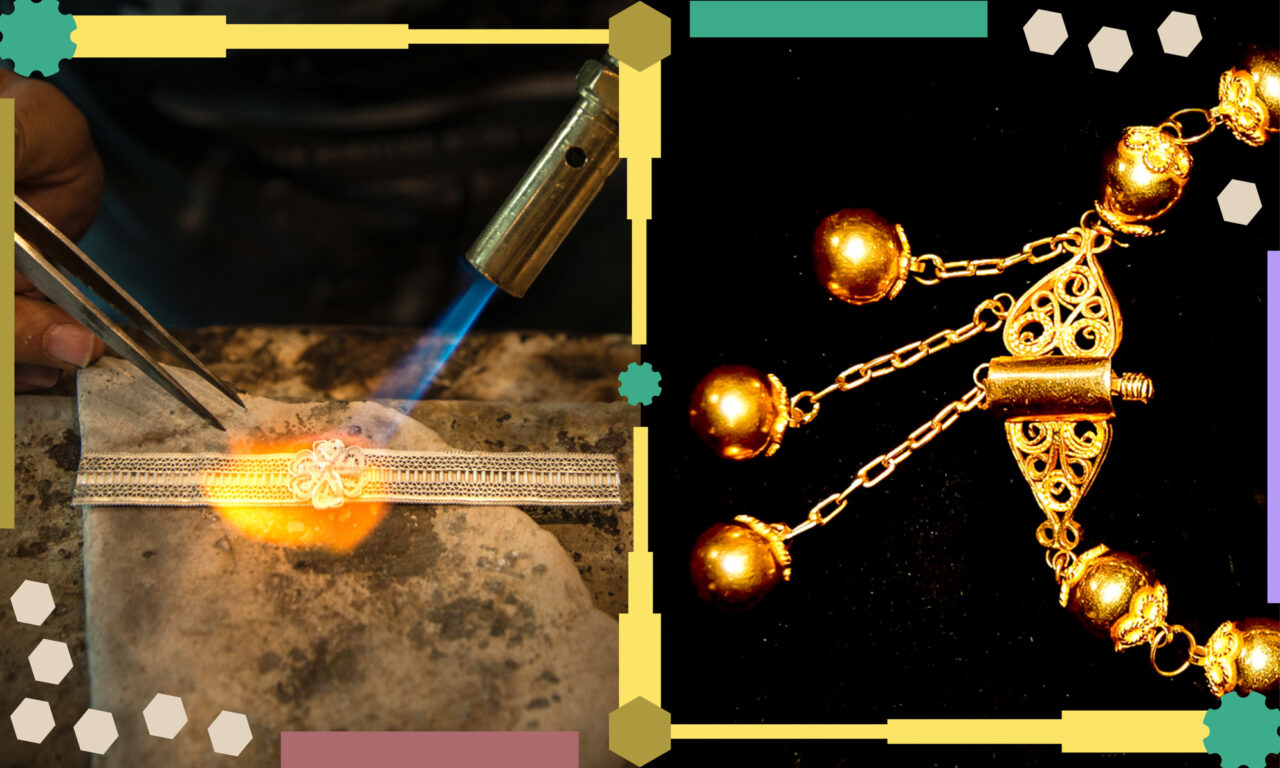

On the other hand, findings from human settlements that date as far back as the Neolithic Period reveal that the region did indeed play a pioneering role in copperworking. It could be said that this role played by the region nurtured an economic and cultural streak that spreads across millennia. Along with gold and silver, coppersmithing, too, became a significant production activity for the city, and a craft that shone especially in the hands of non-Muslim peoples.

We will take the story of copper in Diyarbakır from those single beads [discovered in excavations] that have reached the present day to how it today has become confined to the souvenir industry.

If we go back three thousand years from the present day, we see that the city of Diyarbakır is referred to by the names Amid, Amidi, Amida, Kara Amid. The name Diyarbekir eclipsed the city’s other names in the common era and although there are various theories explaining its roots, the most popular view is that the word Diyar-ı Bekr [“land of the Bekr”] indicates the Arabic tribes that settled in the area.

Atatürk came to the city on 15 November 1937 and began the speech he held following the concert given in his honour at the Halkevi [lit. ‘house of the people’] in the evening with these words: “Twenty years later, I am once again in Diyarbakır. In this most beautiful and most modern building of the world, listening to a piece of modern, excellent music… I am sure you appreciate the scale of my pleasure and happiness I now feel in the company of a civilised people of humanity, at this house of the people. I feel elated to have the opportunity to record this in history books.” This speech also designated the new name of the city by pronouncing it for the first time, and the next day, the city’s new official name was set as Diyarbakır.

This name change had, in fact, a story that went back a year. The principal clerk of the President had requested a study on the etymology of the name Diyarbekir, and the suitability of the name Diyarbakır. The Turkish Language Association and the Turkish Historical Association held a series of meetings throughout a full year, because there were no studies on the subject in hand. Following long meetings of the commission formed for this purpose, it was announced that the old name of the city, Amida, meant copper, or copper coin in the Yakut language, and in view of the fact that the area was a mining site, that Atatürk’s wish of calling the city Diyarbakır was quite suitable. The commission pointed out that this place that was previously known as Amiday was called Diyarbakır, “land of copper”, by the Turks, and that it was “Arabic language and common etymology” that transformed this into Diyarı Bekir. So from now on Diyarbekir had become Diyarbakır.

Source: Şevket Beysanoğlu, Anıtları ve Kitabeleriyle Diyarbakır Tarihi [History of Diyarbakır with its Monuments and Epigraphs], Vol. 1, Diyarbakır Belediyesi, 1987 (first edition).

![The town of Maden, at a distance of 80 kilometres to the city centre, was administratively tied to Diyarbakır until the year 1889. After the mutasarrıflık [governorate] system, it was administratively tied to Elazığ province in 1927. However, Ergani, the other town Maden is always mentioned in the same sentence with since they are so close, is a district of Diyarbakır. This photograph of the mine area was taken in 1918.](https://diyarbakirhafizasi.org/wp-content/uploads/2021/04/2_bakir-1-1280x877.jpg)

Although Diyarbakır, the name the Republic deemed suitable for the city by transforming the Ottoman name Diyarbekir, may have created the illusion that copper was its leading product, the real land of copper was not the city centre, but the town of Maden, 80 kilometres northwest of the city. As for the story of this town and its copper mine, it should be deemed not only the rise and fall of a town, but also a local extension of the history of international colonialism and a modern drama. The current potential that exists in districts such as Ergani, Çüngüş and Dicle, on the other hand, lays dormant with production brought to a complete halt for security reasons.

Dr. Mehmet Atlı, Researcher, Writer

The city received its name due to its proximity to the copper mines in the Ergani region, and coppersmithing was always important for the city. Evliya Çelebi had expressed his admiration for Armenian farriers that transformed their hammer strikes and blows of the bellows into music with a pun, emphasizing that they worked (“kâr”) along with this “hoş avaz” (beautiful song).¹

At a date as late as 1891, outside of the Maden-Ergani region, of the five copper mines in the Diyarbekir area, only the three copper mines in Palu were active, nevertheless the copper industry was still quite important for the city. Coppersmithing was still able to continue to exist during the deindustrialisation process that took place brought on by the integration of Ottoman economy into Western capitalism, from 1885 to 1914. The reason for this was that this craft, which required fine work, had remained in a protected area due to the lack of transport infrastructure, and it could better compete with imported products that had difficulty reaching the region anyway.

Silver and gold were as prominent as copper. Diyarbekir, with its farriers and especially the city’s famous Syriac jewellers, was at a far more advanced position than other Ottoman cities. Bakırcılar Çarşısı, the extant coppersmiths’ bazaar, is worthy of this fame.

Dr. Uğur Bayraktar, Tarihçi

¹ “Ve cemî’i âhengerân-ı Ermenileri çekiç çakıp körüklerin çekerken cümle nağamât-ı mûsikî ederek hoş-âvâz ile kâr u nakş zecel ü tasnîfâtlar okuyarak amel edüp kâr okuyup kâr ederler.” (“All the Armenian blacksmiths make musical melodies as they strike their hammers and blow their bellows. As they play harmonious Kâr and Nakş, Zecel and eastern songs, they both work (kâr) and sing (kâr).”)

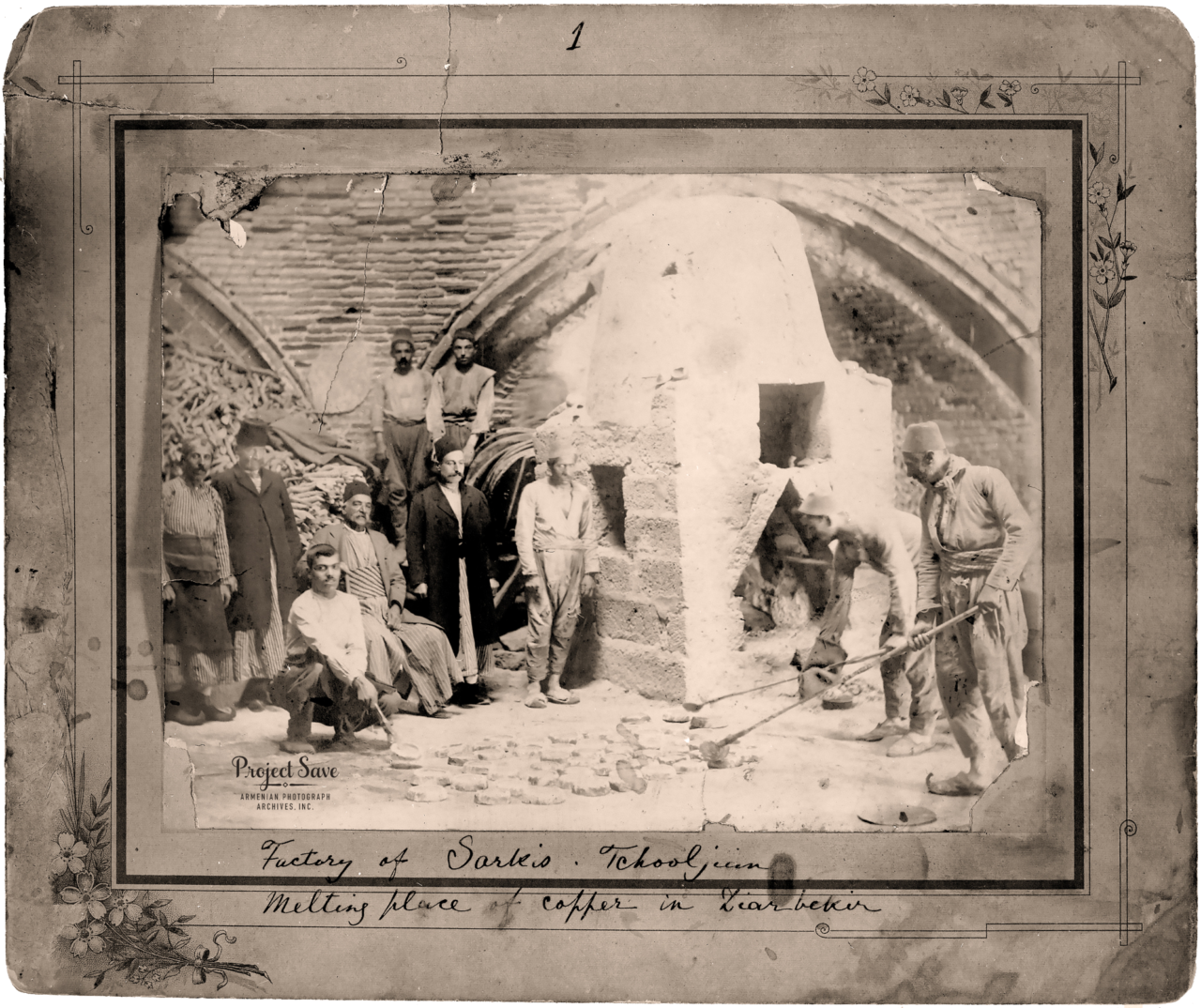

Both at the mine and in the production in the city, non-Muslims formed the majority in copperworking. In the first quarter of the 19th century, of the 743 families that ran the Ergani mines, 300 were Turks, 270 were Rum/Greeks and 173 were Armenians. While Turks and Rum/Greek formed the majority of those involved in copper mining, coppersmithing as a craft was in the hands of Armenians. Before World War I, 230 master coppersmiths produced 65-70 thousand kilograms of copper per annum. After the genocide, only thirty master coppersmiths remained in Diyarbekir, and production was merely 5% of the volume before the war. From the Armenians forcibly deported upon the orders of Talat Paşa, a certain group, the majority of which was craftspeople, had been selected to remain in Diyarbekir. In this way, a limited number of Armenians had survived.

Uğur Bayraktar

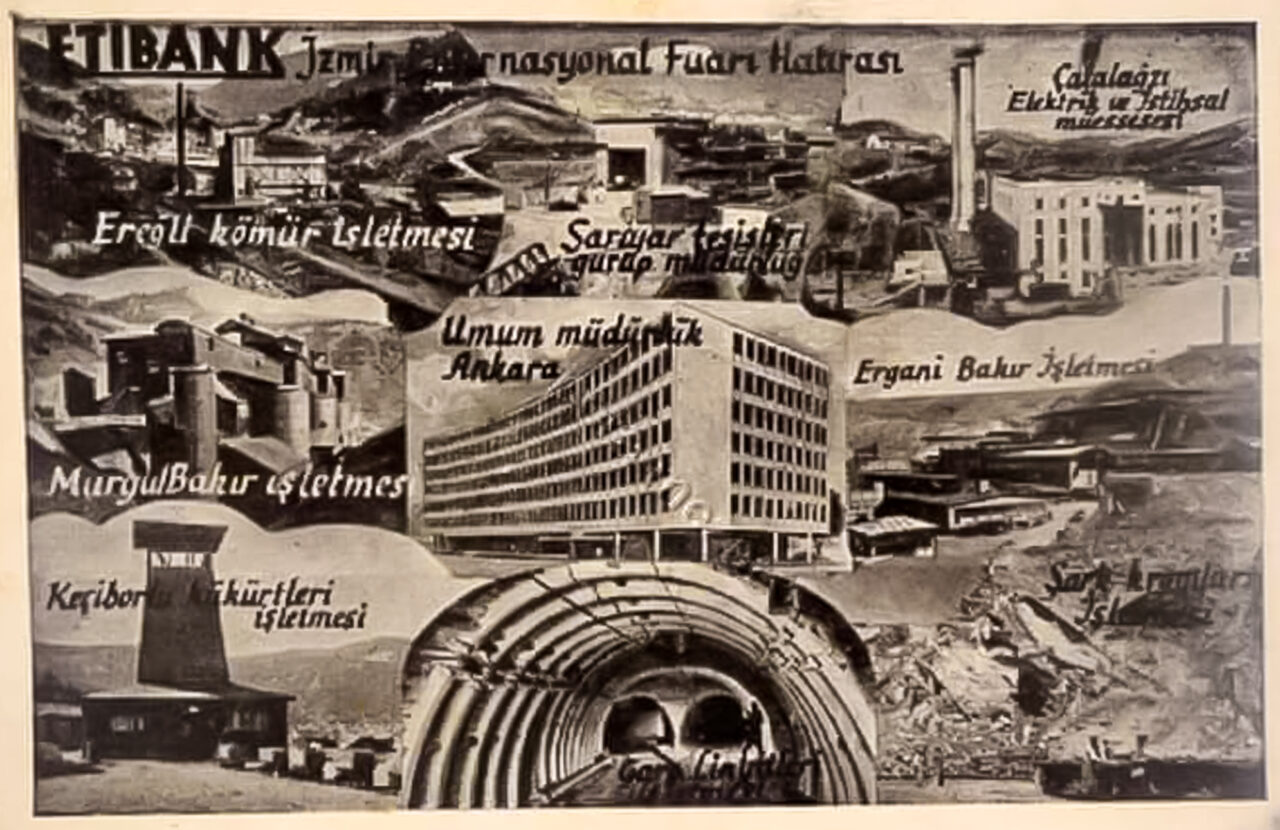

Following Celal Bayar’s visits to the region from 1934 to 1936, the decision was taken to reactivate this industry that was once developed by the Armenians. With improvement work carried out with guidance from German experts at the copper mines under the control of Etibank, a state institution, production volume reached 24 tonnes per annum. 16 tonnes of this was exported to Germany, the United Kingdom and the United States of America, bringing in 17 million dollars.

Following this interest in the early Republican period, copper was only mentioned again in the Second Five Year Development Plan, for the years 1968-72. In the plan, a target was set to increase production at the Ergani Copper Mine, the only heavy industry investment in Diyarbekir and its region, to 1,2 million tonnes per annum.

Uğur Bayraktar

Coppersmithing is Diyarbakır’s gift to the world. Although a few pieces of pure copper were found in Hallan Çemi, the original source of this gift is Çayönü. The fondness for ornamentation and jewellery, like all Neolithic Period people, drove the people of Çayönü to constantly find different stones. Especially the different geomorphological formations in the area around Ergani and Maden contain very colourful layers. It is presumed that copper and malachite was collected in passing during stone collection activities in this area.

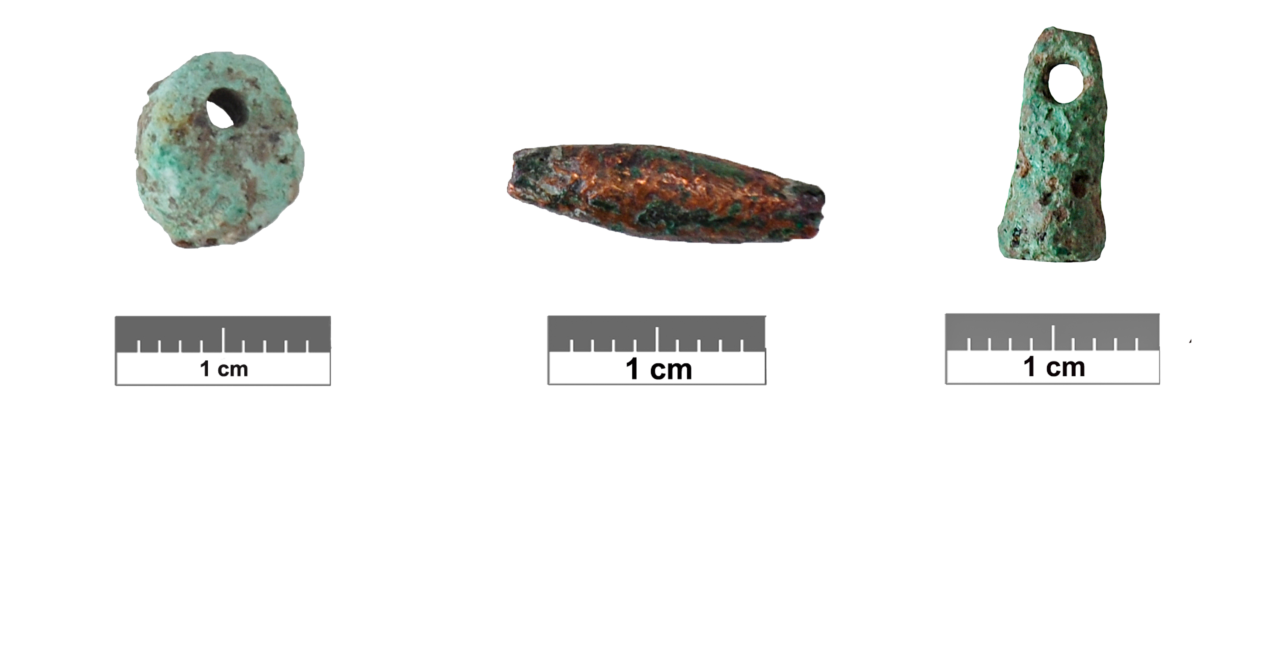

The key part was the next stage. At this stage, pure pieces of copper were forged and shaped when cold, or by half-heating them. In this way, sheets could be made, and these sheets could either be folded to make beads or tools known as biz.¹ The process that began during the middle of the Grid Plan Structures Phase, approximately 10,200 years ago, continued and intensified during the Channelled Buildings and Cobble-Paved Buildings phases. During the Cell-Planned Structures Phase, that is, approximately 8,900 years ago, production dropped, and during the Large Room Buildings Phase, the last phase of the Aceramic Neolithic Period, when a different socio-economic life prevailed, production disappeared completely.

Prof. Dr. Aslı Özdoğan

¹ Sharp, piercing tool.

We unfortunately do not possess sufficient data to tell how much of the copper jewellery and objects in Çayönü were used for domestic use, in exchanges between settlements, as gifts, dowery or if they were produced on order. In Euphrates basin settlements contemporary with Çayönü such as Cafer Höyük (Malatya), Akarçay and Mezraa Teleilat (Birecik) no copper products were found; while we only have a single copper bead from Nevali Çori (Bozova, Urfa). On the other hand, further south in Syria, at Tell Halula on the shore of the Euphrates River, dated to 8,700 years ago, the analysis of copper jewellery discovered in graves beneath the floors indicate the region of Ergani and Maden as a source, and the beads discovered here are identical with those discovered at Çayönü.

It is considered that the copper biz and malachite beads discovered in Tell Magzalia in the Sinjar Plain, a contemporary settlement with Çayönü, could have originated in Ergani. Analysis of the single copper bead discovered at the Ali Kosh settlement in the Deh Luran Valley of Iran reveals its similarity with the manufacturing process of Çayönü beads. In a more general framework, on the basis of isolated findings we have, we infer that the copper jewellery produced in Çayönü was known or heard of in a broad landscape, however we can claim that they were directly used as a commodity of exchange only on the basis of the Tell Halula findings.

Aslı Özdoğan

Once we arrive at the early First Pottery Neolithic and the pre-Hassuna culture period, in certain settlements in Northern Mesopotamia, in the 3rd and 4th phases of Tell Sotto, three copper beads were found, two of which were found in a baby’s grave and also, in the older layers of the 1st phase of Yarim Tepe settlement, a disc-shaped copper bead, and a ring made of bent copper wire. However, the fact that copper objects are both few in number and that there are no traces of their production, gives rise to the thought that they were passed down and inherited from the Aceramic Neolithic Period. The single copper bead discovered at Sumaki Höyük in Beşiri, Batman, is also identical to those in Çayönü and must have arrived here in a similar manner. There are many copper beads among the various stone beads on the jewellery of the alabaster figurines discovered in the burial chamber beneath a structure at the Tell es Sawwan settlement of the same period, in the Tigris Basin in Central Iraq.

The relative spread of the use of copper took place during the Halaf culture period. The Halaf people, who led a semi-sedentary life in a wide area that extended from Muş to Van, and Mid-Mesopotamia in the south, had developed an interest in objects with vivid colours and especially obsidian, and pots and pans with lush patterns. The variety of objects produced increased after the invention of the copper melting process, thus increasing interest in copper mine reserves.

Aslı Özdoğan

“My father was a coppersmith. There was the old Bakırcılar Çarşısı [Coppersmiths’ Market] in Diyarbakır. It was to the south of Buğday Pazarı [Wheat Market], of Ulu Cami [Great Mosque]. At Saman Pazarı [Haymarket], right next to it, in the early morning hours, hay and animal feed brought from the villages would be sold in sacks. Bakırcılar Çarşısı, Saman Pazarı, Peynirciler Pazarı [Cheese Market], Kömürcüler Pazarı [Coal Market]… Kömürcüler Pazarı was in Yanık Çarşı [Burned Market], which we called Çarşiya Şewitî. When buildings were made, that market disappeared, too. Buğday Pazarı has now become Spotçular Çarşısı as you know.

Buğday Pazarı was Diyarbakır’s Kapalıçarşı [the Grand Bazaar of Istanbul]. In one section there were the drapers we called ‘bezzaz’. Most of them were Jewish. Right next to it, in the Sobacılar Çarşısı [‘Stovemakers Market’], most shopkeepers were Armenian. Further down, there was Çulcular Pazarı [‘Horseclothmakers Market’]. Here, saddles, which we called palan [frameless saddles], were made for horses, and excuse my expression, donkeys. Those master craftspeople were Muslim and Armenian. Neighbourhood relationships were great. Both at home, and in the shops and markets.

For instance, in my childhood, my father used to take me to the shop, early in the morning. I remember very well, one day, a citizen came with a copper tray in hand, saying, ‘It needs to be mended’. My father told the man, ‘I’ve already had my first customer of the day, take it to my next-door neighbour, he’ll do it’. Then I asked my father, ‘Dad, a customer came, why did you send him away?’. He replied, ‘My son, you’ll understand when you are older’. That’s how good neighbourhood relations were. The neighbour to whom he sent the customer was Armenian. There were also a lot of Jews in the Wheat Market. There was no discrimination between Armenians, Jews and Muslims. Towards the evening, in the mid-afternoon, everyone would gather in a shop and chat about the important events of the day. Especially during World War II… what did the Germans do, the Russians and the French, too, that was the topic of the debate. The relationship between people was great in the neighbourhood, too. For instance, when someone fell ill in our household, it was always our Armenian neighbours who first rushed to help.”

From an oral history study carried out with journalist and researcher Mehmet Mercan, who was born in 1935 in the Alipaşa neighbourhood of Diyarbakır

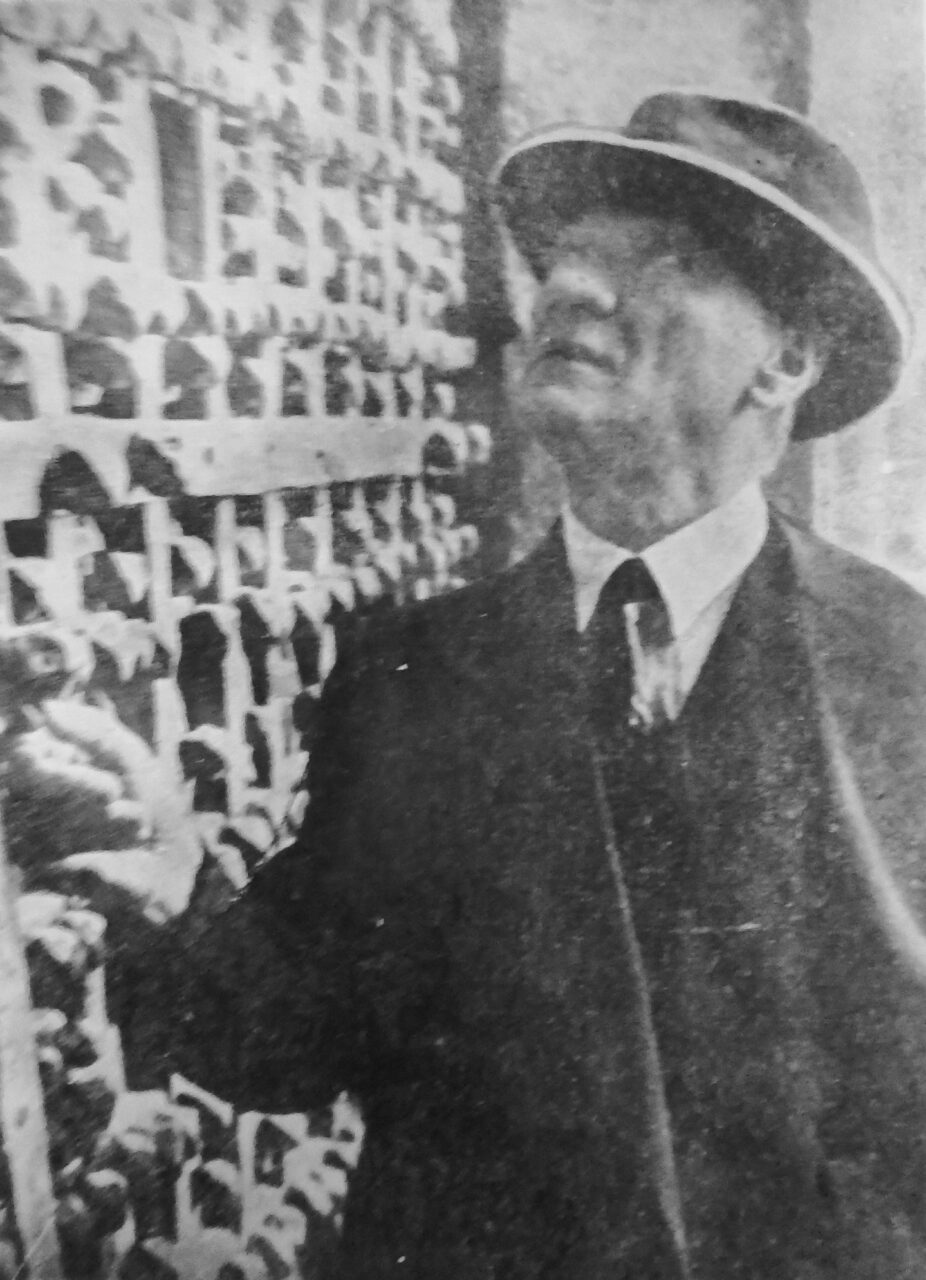

![Author and researcher Mıgırdiç Margosyan, in his book titled “Tespih Taneleri” [“Rosary Beads”] also told the story of his one-day tinsmith apprenticeship.](https://diyarbakirhafizasi.org/wp-content/uploads/2021/04/10_bakir-1280x854.jpg)

“During those years when I began work as a tinsmith’s apprentice, I didn’t have the slightest idea about tinsmithing. All I knew was this, on the eve of every religious holiday, all the pots and pans, including the copper sini [tray], tava [pan], tencere [pot], ‘kuşğhana’ [saucepan] and uskura tas that twirled and whirled in my mother’s hands in the kitchen, would be loaded onto the back of an apprentice who would come from Pese’s shop, head out to be tinned, and would return, bright and sparkling in a day or two.

Once I had seen how our huge tray returned home with its face shining bright like the moon, leaving at the tinsmith’s shop its derelict condition that stood out even among our pale pots and pans, their copper visible in parts; I, too, wanted so much to become a tinsmith like Pese Ohannes… That is why, the day my father took me by the hand to become a tinsmith’s apprentice, my happiness knew no boundaries.

(…) Pese’s shop was on the corner of Sobacılar Çarşısı [‘Stovemakers Market’] and Kazancılar [‘Boilermakers’], or Bakırcılar Çarşısı [‘Coppersmiths’ Market]. While on one side of this long and very narrow shop undermasters carved off pieces of sheet copper, passed them through a roller, shaped and then riveted them amidst the noise of banging hammers to eventually make stoves, on the other side of the shop, pots and pans were tinned.

(…) However, my tinsmith apprenticeship lasted only a day. When I returned home covered in dirt from head to toe, and my hands covered in scars, my mother was not pleased at all, and she complained to my father when he came home in the evening.”

Mıgırdiç Margosyan, Tespih Taneleri [Rosary Beads], Aras Yayıncılık, 2019, p. 63-65.

The copperworking adventure of the city has been shaped in a postmodern framework, on the basis of its associations with the Diyarbakır name, and in a slightly coincidental manner; not on a powerful tradition, but with contemporary urban legends and advertising slogans that have a strong tendency for “kitschification”… Tinned copper pots and pans, which for a long time were probably owned by the wealthy, became everyday objects for ordinary citizens, too, for a brief period, however, that didn’t last long. Once steel, porcelain, glass and plastic became widely available, copper remained only in nostalgic stories and second-hand shops.

For a long time now, the craft had regressed to an almost showpiece, touristy, gift-oriented level in the few shops left in Balıkçılarbaşı, but there have been recent efforts to revive the industry with new initiatives. It seems difficult, and in fact, impossible for copperworking to make a leap “worthy of the city’s name”. In order to understand this, we need to take a closer look at the impasses of security policies, and at Maden, once a township of the Diyarbekir vilayet, and today, a faded-star of a district in Elazığ province.

Mehmet Atlı

Translation: Nazım Dikbaş

BIBLIOGRAPHY

Uğur Bayraktar

• Brant, J. (1836) “Journey Through a Part of Armenia and Asia Minor, in the Year 1835”, Journal of the Royal Geographical Society of London, 6: 187-223.

• Cuinet, V. (1891) La Turquie d’Asie, géographie administrative: statistique, descriptive et raisonnée de chaque province de l’Asie Mineure, Vol. 2, E. Leroux, Paris.

• van Bruinessen, M. ve Boeschoten, H. (ed.), (1988) Evliya Çelebi in Diyarbekir: The Relevant Section of the Seyahatname, E.J. Brill, Leiden and New York.

• Quataert, D. (1987) Osmanlı Devleti’nde Avrupa İktisadi Yayılımı ve Direniş (1881-1908), Yurt Yayınları, Ankara. [Turkish translation of: Quataert, D. (1983) Social Disintegration and Popular Resistance in the Ottoman Empire, 1881-1908: Reactions to European Economic Penetration, New York University Studies in Near Eastern Civilization, 1983.]

• Tızlak, F. (1997) Osmanlı Döneminde Keban-Ergani Yöresinde Madencilik [Mining in the Keban-Ergani Region during the Ottoman Period], Türk Tarih Kurumu, Ankara.

• Üngör, U. Ü. and Polatel, M. (2011) Confiscation and Destruction: The Young Turk Seizure of Armenian Property, Continuum, London.

• Yadırgı, V. (2017) The Political Economy of the Kurds of Turkey: From the Ottoman Empire to the Turkish Republic, Cambridge University Press, Cambridge.

Aslı Özdoğan

• Caneva, I., Davis, M., Marcollongo, B., Özdoğan, M. and Palmieri, A. M. (1993) “Geo-archaeology in the Northern Diyarbakır Region”, Essays on Anatolian Archaeology, Bull. of the Middle Eastern Culture Center in Japan, VII, (ed.) T. Mikasa, Harrassowitz, Wiesbaden: 161-168.

• Erim-Özdoğan, A. (2011) “Çayönü”, The Neolithic in Turkey: New Excavations & New Research, The Tigris Basin, (ed.) M. Özdoğan, N. Başgelen, P. Kuniholm, Archaeology & Art Publications, Istanbul: 185-269.

• Maddin, R., Stech, T. and Muhly, J. D. (1991) “Çayönü Tepesi: The Earliest Archaeological Metal Artifacts”, Decouverte du Metàl, (ed.) J. Mohen, Méditerranée Orientale et Proche-Orient, Picard: 375-386.

• Molist, M., Montero-Ruiz, I., Clop, X., Rovira, S., Guerrero, E. and Anfruns, J. (2009) “New Metallurgic Findings from the Pre-Pottery Neolithic: Tell Halula (Euphrates Valley, Syria)”, Paléorient, 35(2): 33-48.

• Özdoğan, M. and Özdoğan, A. (1999) “Archaeological Evidence on the Early Metallurgy at Çayönü Tepesi”, The Beginning of Metallurgy, Bochum: 13-22.

• Rosenberg, M. (1999) “Hallan Çemi”, Neolithic in Turkey, The Cradle of Civilization, New Discoveries, (ed.) M. Özdoğan and N. Başgelen, Arkeoloji ve Sanat Yayınları, Istanbul: 1-19; 25-33.